Product Training

IQ - Industry Qualification program

Controls and Lubrication Products - Product training

- HOERBIGER offers Hands-On training on different products

- Each session lasts for two days covering one product

- Training sessions in person in Vienna (large groups customized off ering at site)

- Costs per session including training material, coffee breaks and lunch, excluding travel and accommodation

- Deliverables: Practical sessions and training material plus attendees certificate

- Training Language: English

Combination between different product training and knowledge sessions available!

Since nearly three decades HydroCOM is the world-standard when it comes to stepless compressor capacity control. It does so by utilizing the reverse flow concept. The idea is simple. HydroCOM is delaying the start of compression inside the cylinder by actively keeping the suction valves open for a precisely controlled amount of time, until the desired capacity is reached – fully automatic, with every revolution of the compressor. Gas that is not required and does not need to be compressed can simply flow back to the suction side - hence the name reverse flow control. The required unloading force is generated by oil pressure. A solenoid valve is used for control. HydroCOM eliminates the need for energy-wasting bypass valves, saves energy while at the same time improving process control, and reduces the compressors OPEX and CO2 emissions.

Order No. D10888

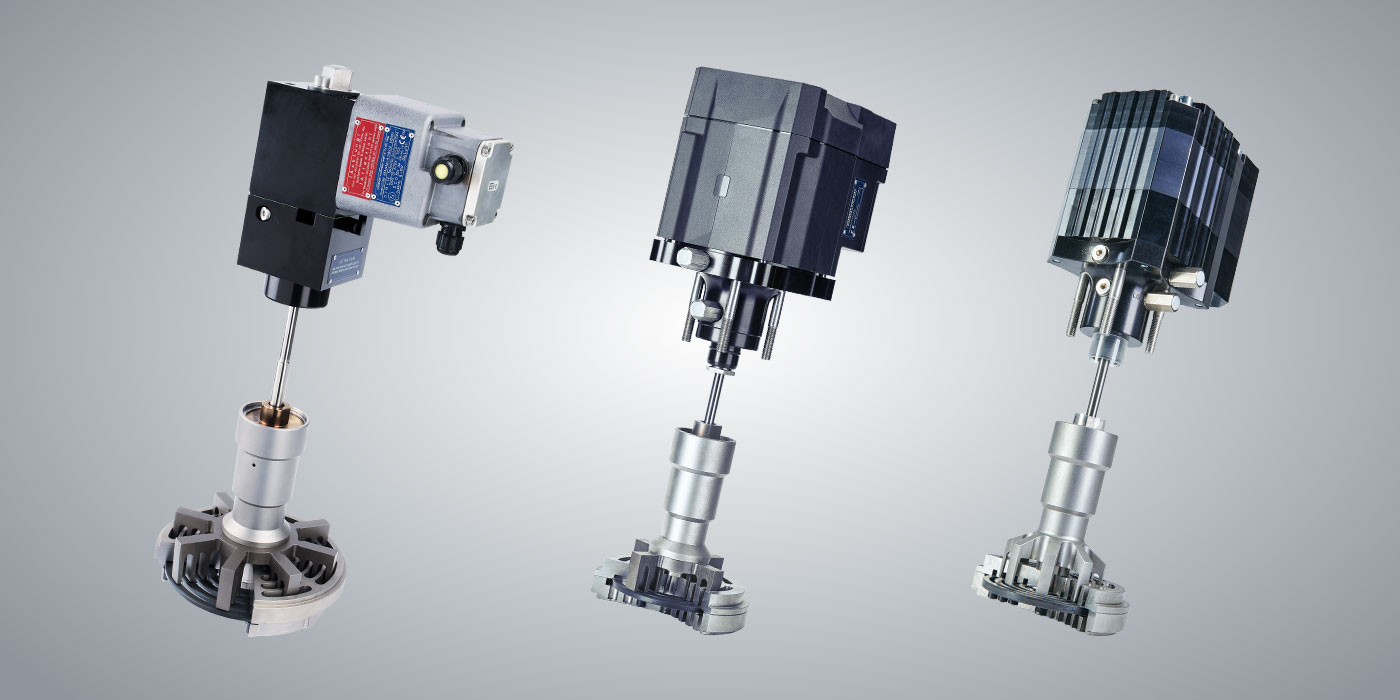

With the market launch of the fully electric eHydroCOM systems a cutting edge, completely oil-free solution for reverse flow control became available. The unloading force to keep the suction valve open is generated by means of an electromagnet. This system architecture renders hydraulics obsolete and allows highest standardization, thus simplifying installation, maintenance, repair, and asset management. With eHydroCOM compressor capacity control is easier than ever before. Two distinct system versions with different application limits are available.

eHydroCOM HD – Heavy Duty Single Stack Actuator

A system design to perform under heavy duties. This version offers best in class payback time and total cost of ownership, while being suitable for most applications.

Order No. D10890

eHydroCOM XD – Extreme Duty Double Stack Actuator

The most powerful and compact system for extreme duties. Ready for the most demanding high force or high-speed applications in the industry.

Order No. D10889

Reliable cylinder lubrication is one of the most sensitive issues for the operation of highly sophisticated reciprocating compressors. The wrong dosage can cause damage through wear or over-lubrication. This means: unscheduled downtime, costly production losses or consequential damage in other parts of the production. Time to delegate this important task. The XperLUBE system is designed to increase the performance and cost efficiency of your compressors. It does so by utilizing the common-rail concept, where each lubrication point is equipped with an individual injector, consisting of a solenoid valve for oil flow control and a sensor for oil flow monitoring. XperLUBE supplies your compressor with exactly the right amount of lubricant. Always. Under all conditions.

Order No. D10891

Can be merged with ”Knowledge Sessions“ depending on needs.

Working principles & Design Characteristics

- Common Failures & Troubleshooting Principle

- Assembly, Disassembly and plug-in tests

Dates and locations

HydroCOM | Order no. D10888 | Mar. 09-10 | Sep. 07-08 | Sep. 14-15 | 2026 | Vienna | Book here |

| Jan. 14 | Mar. 11 | May 12 | 2026 2026 | Houston* | ||

| Jul. 07 | Sep. 15 | Nov. 11 | ||||

| eHydroCOM HD | Order no. D10890 | Mar. 23- 24 | Oct. 12-13 | 2026 | Vienna | Book here | |

| eHydroCOM XD | Order no. D10889 | Apr. 08-09 | Nov. 03-04 | 2026 | Vienna | Book here | |

| XperLUBE | Order no. D10891 | Mar. 11-12 | Sep. 09-10 | 2026 | Vienna | Book here |

All details and the training registration form can be found in our brochure.

General Terms & Conditions

Find our entire Training offering here

How can we help you?

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.